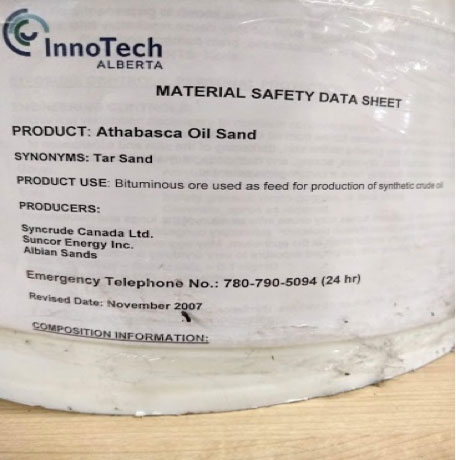

The patented technology was employed to confirm if the oil sands often known as Tar sands would produce oil following the treatment process. About 20 pounds or 10 kg of oil sand sample was imported from Canada for the study. The sample was sent by Innotech Canada or Canada Innovates.

Laboratory Experiment:

The sample of oil sands was evaluated to confirm if VaporRemed is effective in the bioremediation of the oil sands. A known quantity of oil sand was taken in three conical flasks and 25 ml of VaporRemed was added to each of the flasks with one control. The flasks were placed on a rotary shaker and were shaken at 180 rpm. At the end of 96 hours or 4 days, a film of free-floating oil was observed on the surface in flasks treated with VaporRemed. The control flask did not show any oil.

Testing of the process:

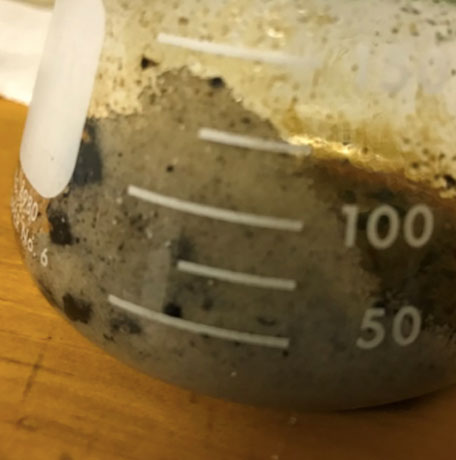

The initial studies showed promise that VaporRemed was effective in the bioremediation of oil sands by producing free oil. 20 grams of the oil sand was taken in a different set of the conical flask. The sand was first pretreated with a single spray of starter solvent diesel and this was immediately followed by a spray of VaporRemed in the ratio of 1:2. One could see the oil being released in the flask. About 10 ml of water was added to this to draw out oil from the sand into a larger flask. This was repeated multiple times till the sand looked clean and free from any oil.

Almost 25 ml of oil was collected in the flask from 20 grams of oil sand. The sand as seen below was fairly clean. It is seen that the amount of oil produced is in the ratio of 1:1.

The results were encouraging and the studies were extended in a prototype system developed with the local engineering firm. The prototype is known as Fuel Oil From Oil Sands 1 or FOFOS 1 as seen below.

The system consists of a reaction vessel with a central drain connected to an Oil Water Separator through a ball valve. The reaction vessel is painted green and the oil-water separator is black. The oil-water separator separates oil and water from the oily water released by the reaction vessel. Oil collected is free from water and the water collected is free from oil. It is proposed to re-use the water collected from the water outlet and thus conserve water.

10 pounds or 5 kgs of oil sands was taken in the reaction vessel and as described above the sand was sprayed with starter solvent Diesel and this was immediately followed with a spray of VaporRemed two times the volume of diesel. Immediately, water is released from the ring at the top of the reaction vessel. The oil released is collected by the water and is carried to the oil-water separator where the oil is separated from the water.

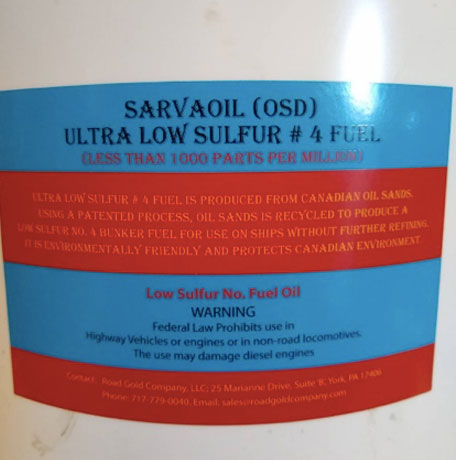

The oil was sent for analysis and was found to be closer to low sulfur No. 4 fuel oil. The entire process is carried out in cold water and there are no emissions during the process. The fuel produced by the system is not dirty synthetic crude or dilbit or diluted bitumen. It is a more refined oil and can be directly used in many industrial applications including ships that require low sulfur bunker fuel.

The volume of oil collected:

The process was continued multiple times till the sand looked clean. Oil was collected at the oil port of the oil-water separator. The bucket was weighed and the weight of oil was found to be 26 pounds or nearly 13 kilograms. Based on this information it is considered that in this process oil produced is more than double the weight of oil sand. The oil produced is termed as SarvaOil (OSD). OSD stands for Oil Sands.